| Product appearance | Product name | Stroke X/Y/Z mm |

Spindle taper type Representative Type |

Max. spindle speed min-1 |

Number of storage bottles (standard)pcs |

Machine weight Kg |

|---|---|---|---|---|---|---|

|

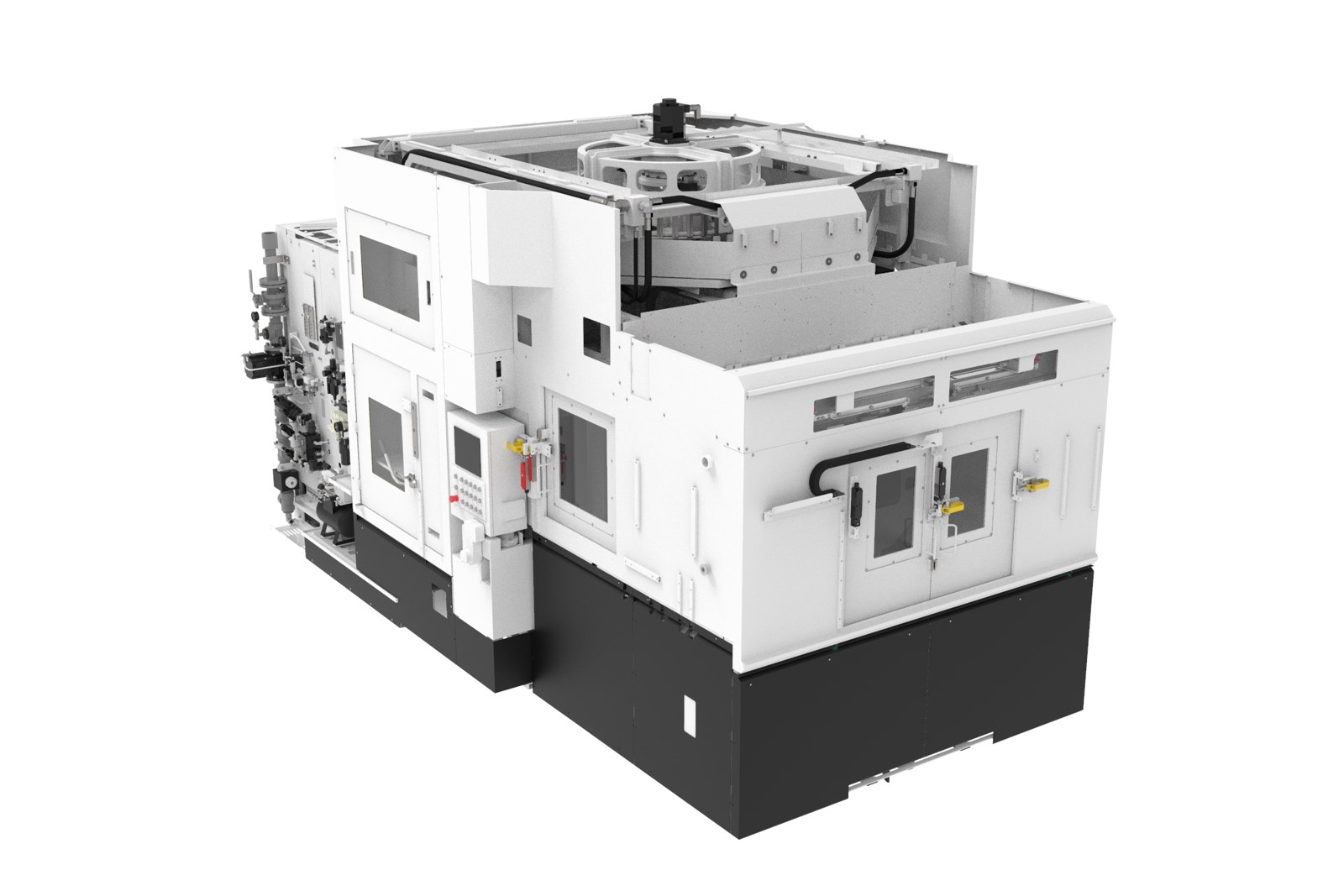

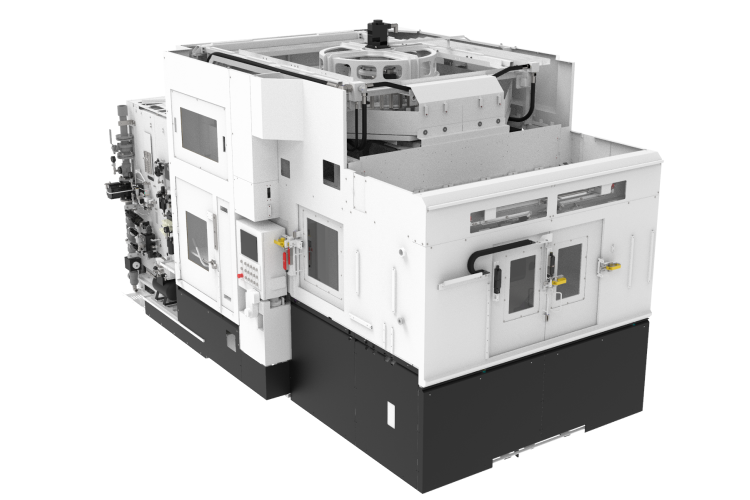

CX500 (2-APC) | 800 / 800 / 900 | HSK-A63 | 20,000 | 60 | 18,000 |

| Product appearance | Product name | Stroke X/Y/Z mm |

Spindle taper type Representative Type |

Max. spindle speed min-1 |

Number of storage bottles (standard)pcs |

Machine weight Kg |

|---|---|---|---|---|---|---|

|

N30Hi | 400 / 300 / 300 | BT30 | 12,000 | 16 | 2,400 |

|

N3Q(Special) | 1,650 / 410 / 400 | HSK-A40 | 12,000 | 16 | 18,000 |

|

N40HC | 500 / 200 / 400 | HSK-A63 | 8,000 | 20 | 6,500 |

|

N40Hi | 500 / 500 / 400 | HSK-A63 | 12,000 | 20 | 12,500 |

|

NH4555Y | 500 / 500 / 500 | HSK-A63 | 12,000 | 20 | 9,400 |

|

TMC-779 (2-APC) | 660 / 660 / 850 | KM6350 | 12,000 | 60 | 12,000 |

|

NX400 | 600 / 600 / 700 | HSK-A63 | 12,000 | 39 | 23,000 |

|

NX450 | 800 / 600 / 900 | HSK-A100 | 10,000 | 29 | 23,500 |

|

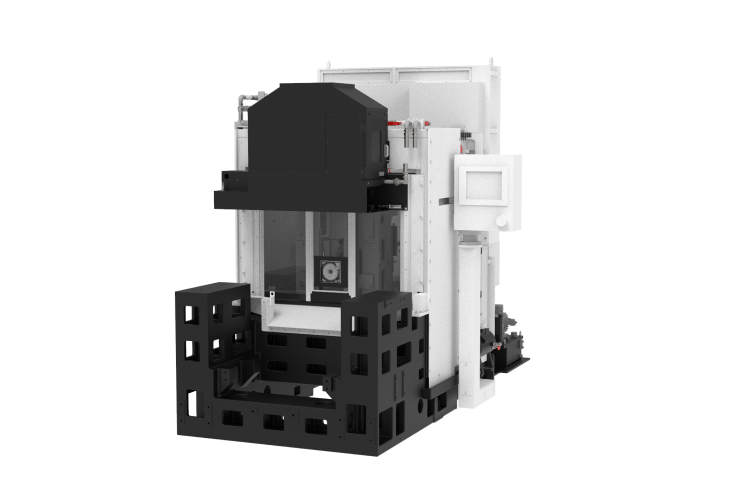

NX500 | 1,500 / 800 / 900 | HSK-A100 | 6,000 | 64 | 43,000 |