| Machine specification items | Unit | Standard specification value |

|---|---|---|

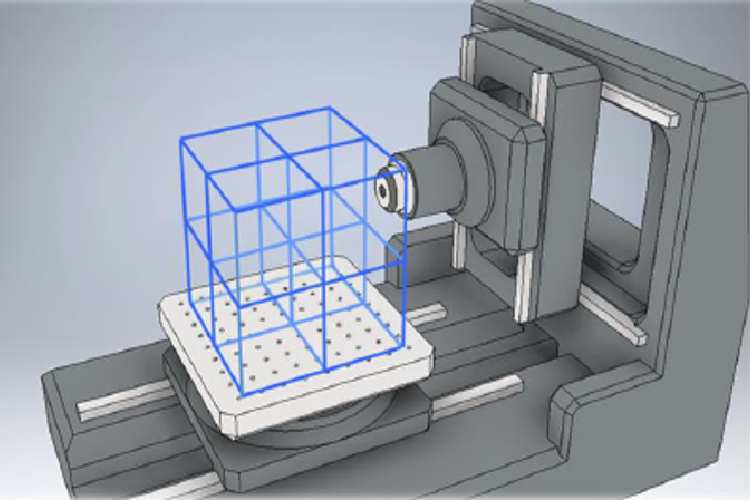

| pallet | mm | 500 × 500 (2-sided swivel type, top side: M16 tap) |

| Stroke XYZ | mm | 800 / 800 / 900 |

| Spindle taper type | Type | HSK-A63 |

| Spindle speed | min-1 | 100~20,000 |

| Spindle motor | Kw | Output (10 min / continuous) 37 / 26 |

| Fast forwarding speed | m/min | 60 |

| Number of tools stored | (Somebody's) side | 60 |

| Max. tool length/Max. tool diameter | mm | 400 / Φ250 |

| Control unit | Type | FFANUC 31i-B PLUS series |

| Machine Size | mm | W2,985×D6,175×H3,280 |

| Machine mass | Kg | 18,000 |

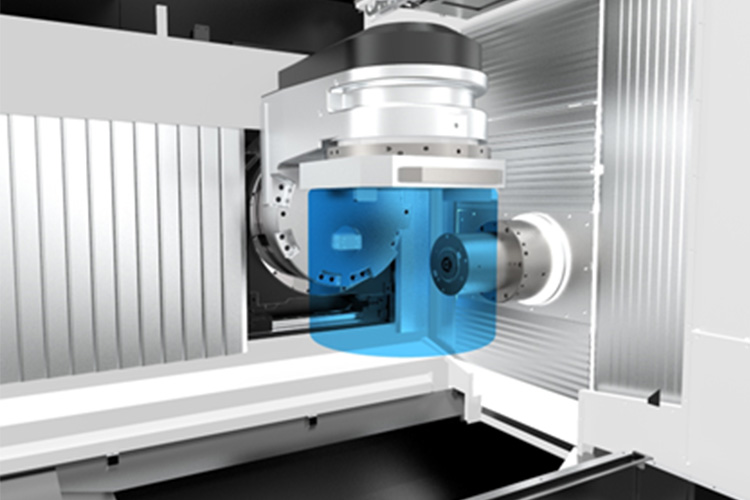

The following video introduces the machine features of the CX500

Model : Vacuum chamber

Material : A7075

Model : Glass (Tulip)

Material : A7075

KOMTAS is an IoT tool that visualizes equipment status by transmitting information from the equipment itself.

It converts detailed machine tool data, such as various NC information and optional analog sensors, into human-readable information.

By monitoring and managing the information, it supports investigation of the cause of machine trouble and predictive maintenance.