・High-speed transfer system

・Multi-complex inspection

・Inline/Stand-alone support

・Teaching function, etc.

・Image capture, illumination, synchronization

・Measurement, recognition, defect detection, quantitative evaluation

・Micro inspection

・Direct control

・Parallel processing, pipe processing, proprietary algorithms

・Image Correction Functions

・Energy saving, reduced CPU load

・deep learning

| Product appearance | Product name | Process | Inspection target | Function |

|---|---|---|---|---|

|

Wafer inspection equipment | Surface and internal inspection | Silicon wafers (semiconductors, solar cells) | ・Crack detection ・Stain detection |

|

LCD glass substrate inspection system | Surface inspection | Glass | ・Defect detection ・Whole width measurement |

|

Li ion battery electrode plate inspection | Surface inspection | Sheet | ・Defect detection ・Shape measurement ・Dimensional measurement |

|

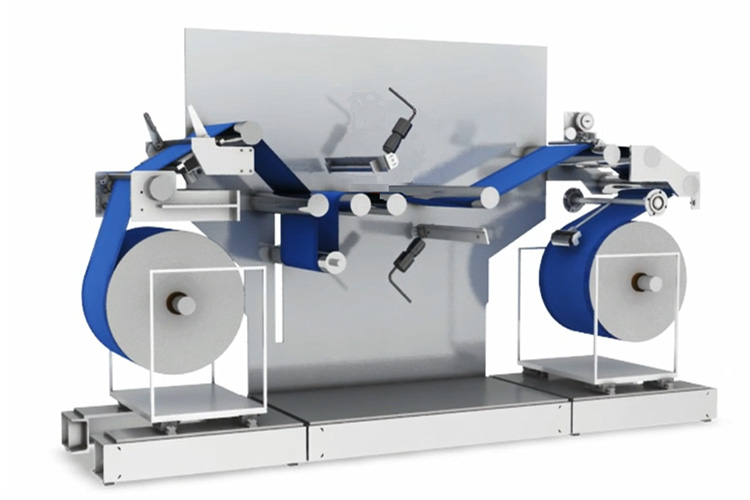

Plain web inspection system | Surface inspection | Sheet | ・Defect detection ・Contrast measurement ・Dimensional measurement |

|

Floating seal inspection | Surface inspection | Metal | ・Defect detection ・Dimensional measurement |

|

Piston rod inspection | Surface inspection | Metal | ・Defect detection ・Dimensional measurement |

|

Glitter inspection machine | Surface and internal inspection | Sheet | ・Glare measurement |

|

LED Inspection equipment | Internal inspection | LED | ・Defect detection ・Dimensional measurement |

|

Knitting defect inspection equipment | Surface and internal inspection | Knit | ・Defect detection |

| Product appearance | Product name | Process | Nspection target | Function |

|---|---|---|---|---|

|

Headlight Focusing Equipment | Assembly Welding | Headlamps | ・Position detection ・Assembly ・Resistance welding |

|

Automatic needle caulking machine | Assembly | Needle and thread | ・Positioning ・Crimping |

| Product appearance | Product name | Process | Inspection target | Function |

|---|---|---|---|---|

|

Headlight focusing device | Assembly Welding | Headlamp | ・Position detection ・Assembly ・Resistance welding |

|

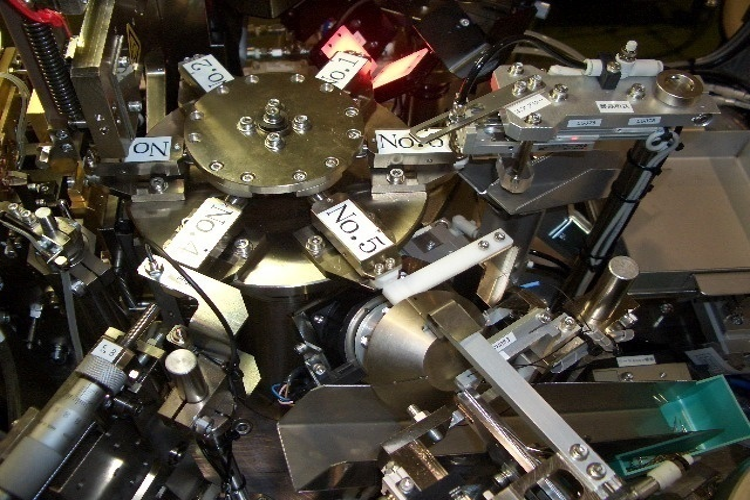

Lead assembly equipment | Welding | Electrodes | ・Position detection ・Assembly ・Resistance welding |

|

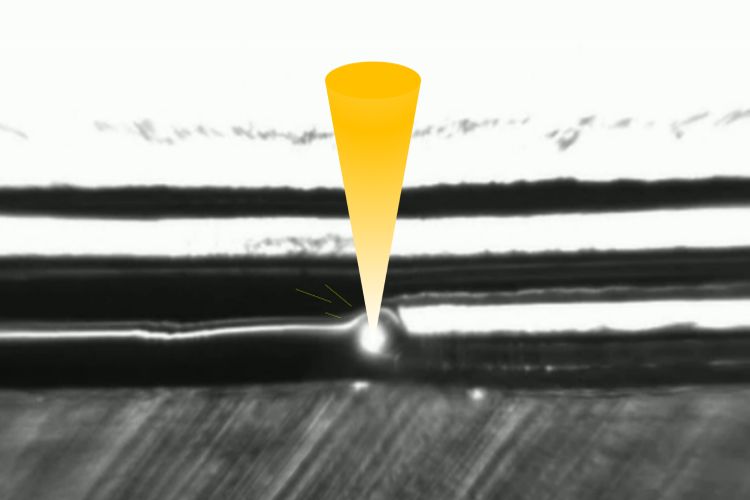

Flat wire welding equipment | Welding | Motor stator | ・Position detection ・Laser welding |