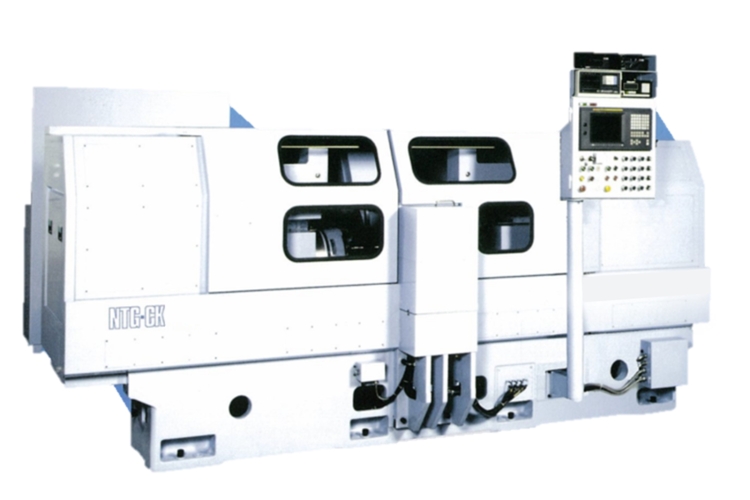

| Workpiece transfer method (example) | Production output | Summary |

|---|---|---|

| Gantry transfer | Mass production | 2-arm type. The grinding machine has an automatic opening/closing ceiling cover. |

| Ceiling-mounted robot | Mass production | When a large number of postures are required to carry workpieces to each machine |

| Manual Conveyor | Medium volume | Manual pallet transfer system with free conveyor |

| Simplified loader | Medium volume | Stand-alone automation with mechanical-type loaders on all sides of the machine |